The Chevy 4.3L V6 engine has been a workhorse in GM trucks and SUVs for decades. First introduced in 1985, this small-block power plant has gone through several design changes and upgrades over the years.

But with so many variations of the 4.3L from carburetor to fuel-injected, which one stands out as the best?

In this blog post, we will explain what is the Best Year 4.3 Chevy Engine and we’ll compare the key differences between model years and highlight the pros and cons of both classic and modern Chevy 4.3L engines.

Whether you’re restoring an older truck or shopping for a used SUV, read on to learn which 4.3L version is considered the most reliable, powerful and efficient.

Original Chevy 4.3L Vortec (1985-1995)

The original 4.3L V6 debuted in 1985 as the replacement for Chevy’s 3.8L V6. Dubbed the “Vortec 4300”, this engine design continued largely unchanged through 1995 across Chevy/GMC pickups, vans, and SUVs. The key traits of the first generation 4.3L include:

- Carbureted induction – Early 4.3Ls used a Rochester 2-barrel carburetor for fuel delivery. This provides great response but poorer efficiency compared to later fuel injection.

- Mechanical throttle body fuel injection (TBI) – In 1988, the 4.3L switched to throttle body injection for improved fuel economy and emissions. Performance lagged due to lack of sequential injection.

- Reliable and simple – The original 4.3L is known for no-fuss operation with very few common issues when maintained. Fuel and ignition systems are basic and robust.

- 12-bolt intake pattern – Makes the engine easy to identify. Later 4.3Ls switched to 24-bolt intakes. Aftermarket support is wide for mods and upgrades.

- Hydraulic roller lifters – Quiet valve train operation. Later 4.3Ls went to cheaper flat tappet cams.

- Cast iron cylinder heads – Excellent durability and heat dissipation but added considerable weight over aluminum heads.

The original 4.3L Vortec is regarded as one of the most stone-reliable GM engines ever produced. Simple design, ample torque, and bulletproof construction make the first generation 4.3 a favorite among work truck owners seeking maximum dependability on a budget.

Vortec 4300 Gen 2 (1996-2002)

In 1996, GM introduced an upgraded second generation of the 4.3L V6. Changes included:

- Vortec cylinder heads – New combustion chamber and port design optimizes airflow for better efficiency. Valve size increased slightly.

- Central sequential port fuel injection – Replaced TBI for much improved throttle response, power output, and mileage. O2 sensors added.

- 24X crankshaft and cam sensor – For more accurate ignition timing control and smoother operation.

- Roller tipped rocker arms – Reduced friction for increased horsepower compared to old flat tappet valvetrain.

- Distributorless ignition – Coil packs fire each cylinder individually eliminating maintenance prone distributors.

The Gen 2 4.3L Vortec corrected most of the shortcomings of the original design while retaining its core simplicity and reliability. Horsepower jumped from 190 to 200, while torque increased from 260 lb-ft to 255 on models with central fuel injection.

This generation saw expanded usage outside of trucks in the Chevy S10, Blazer, Jimmy, Bravada, Isuzu Hombre and Oldsmobile Bravada. It strikes an excellent balance between the durability of the Gen 1 and modernization of the Gen 3. For many, the Gen 2 4.3L represents the pinnacle of the 4.3’s workhorse dependability.

Vortec 4300 Gen 3 (2003-2013)

In 2003, the 4.3L Vortec was significantly updated with a modern aluminum block and heads. Dubbed the Vortec 4300 “LU3”, changes included:

- All aluminum construction – Shed up to 75 lbs of weight over cast-iron engine. Improves efficiency and reliability.

- Coil-on-plug ignition – Individual coils mount directly over each spark plug eliminating spark plug wires. More precise timing.

- Displacement on demand – Active fuel management system cuts off cylinders during light load for improved fuel economy.

- Electronic throttle control – Drive-by-wire replaces mechanical linkage for finer throttle adjustment. Integrates with variable valve timing.

- Sequential multi-port fuel injection – Separate injector per cylinder fine tunes fuel delivery for maximum precision.

The Gen 3 modernized the 4.3L for continued truck/SUV usage but saw expanded use in crossover vehicles like the Chevy HHR and Colorado, GMC Canyon, and Buick Rendezvous.

Aluminum construction, VVT cam timing, and advanced DIS ignition highlight the thorough overhaul. Power output remained similar around 190-200 hp but efficiency took a large leap forward.

This generation represents the most high-tech 4.3L ever produced, though complexity came at a tradeoff of the Gen 1’s stone-age simplicity. The all aluminum 4.3L marked the end of an era before being discontinued after 2013.

Pros of the Gen 1 Vortec 4300

The original 1985-1995 Chevy 4.3L Vortec stands out for these advantages:

- Proven reliability – Simple pushrod design with minimal electronics results in very dependable operation even at high miles.

- Easy maintenance – Basic ignition and fuel systems with mechanical controls are simple for DIY repairs and maintenance.

- Affordable power – Abundant torque from large displacement provides stump-pulling strength without a premium fuel or engine cost.

- Workhorse durability – All iron construction is nearly indestructible. Not necessarily powerful but will run forever when maintained.

- Light duty capability – Early 4.3’s adequate power enables use in light work trucks for hauling and towing around town. 250 lb-ft torque gets the job done.

- Mod potential – Responds very well to upgrades like intake, camshaft, and exhaust for extra horsepower. Strong lower end handles boost well.

- Parts interchangeability – Many components swap directly from Chevy 350 V8 allowing cheap and easy repairs with readily available parts.

The Gen 1 4.3L lacks sophistication but nails the fundamentals of affordability, reliability, and simplicity that budget-focused truck owners need. Its limitations become character traits proving its versatile dependability.

Cons of the Gen 1 Vortec 4300

Downsides of the original 1985-1995 4.3L include:

- Low horsepower – Rated between 160-190 hp, output is meager by modern standards. Feels especially sluggish in larger vehicles.

-primitive induction – Both carb and throttle body injection lack power and response compared to modern sequential systems. Suffers from flat spots off idle.

- Poor fuel economy – Heavy iron design combined with inefficient induction keeps miles per gallon to mid teens range at best.

- Minimal emissions controls – Does not meet modern standards so Cold War era tech limits use in some areas.

- High maintenance ignition – Distributor caps, rotors, wires and plugs need frequent attention compared to coil packs.

- Limited refinement – Lots of vibration and noise typical of old-school pushrod V6 designs. Rougher delivery of power.

- Weak valve trains – Hydraulic lifters and weak cast rockers are prone to accelerated wear without hardened parts.

The Gen 1 4.3L is a no-frills workhorse rather than refinement focused. Its dependability and simplicity come at the cost of low power, unimpressive economy, dated tech, and tough NVH. Not an engine for those wanting comfort or efficiency.

Pros of the Gen 2 Vortec 4300

Advantages of the upgraded 1996-2002 Gen 2 4.3L include:

- Power increase – Addition of Vortec heads bumps output to 200 hp and 255 lb-ft torque for noticeably better acceleration.

- Sequential port injection – Greatly improves throttle response and power delivery compared to throttle body systems for a modern feel.

- Increased fuel economy – Up to 15% boost in mpg from improved cylinder heads and multi-port injection.

- OBD2 diagnostics – Scan tool integration for simplified troubleshooting. Check engine light takes guesswork out of problems.

- Distributorless ignition – Individual coil packs are maintenance free and precisely control spark timing.

- Familiar durability – All iron blocks maintain 4.3’s reputation for unbreakable reliability at an affordable price.

- Ideal balance – Gen 2 blends just enough updated technology like sequential injection and DIS ignition with traditional architecture for optimal real world performance.

This generation of the 4.3L V6 hit the sweet spot between old school simplicity and modern enhancements. The longevity and dependability of the original design pairs with noticeable improvements in drivability and economy.

Cons of the Gen 2 Vortec 4300

Downsides of the mid-generation 4.3L include:

- Less torque than Gen 1 – Rearrangement for Vortec heads drops max torque slightly from 260 lb-ft to 255 lb-ft.

- Cheap rocker arms – Switch to stamped steel rockers and flat tappet lifters traded durability for cost savings.

- Limited interior refinement – Rough, truck-like manners remain despite upgrades. NVH levels are still unimpressive.

- Minimal towing capacity – Maximum recommended trailer weight is only 3,000 to 5,000 lbs. Towing large loads stresses the 4.3L.

- Not compatible with E85 – Fuel system components were not designed for high ethanol concentrations. Requires costly upgrades to convert.

- Uncommon platform – Engine bay packaging prevents easy swapping into other vehicles compared to ubiquitous Chevy 350 V8.

- Repairs still require specialized knowledge – Although updated, DIY maintenance remains tricky for those lacking expertise. Dealer diagnosis is often needed.

While a well-rounded package, the Gen 2 4.3L still lacked sophistication compared to contemporary V6 options from competitors. It split the difference between old school simplicity and refinement.

Pros of the Gen 3 Vortec 4300

Modern enhancements of the third generation 4.3L include:

- Lightweight all aluminum design – Shed up to 100 lbs over cast iron for improved handling, acceleration and mpg.

- 55% reduction in parasitic loss – Less friction and lower rotating mass through innovative construction techniques.

- Coil near plug ignition – Individual coil mounting improves reliability and tune-ability. No high tension wires to fail.

- DIS fuel economy – Displacement on demand seamlessly cuts cylinder usage during light load for up to 20% better fuel efficiency.

- Continuous variable valve timing – Optimizes cam phasing for torque, economy and emissions as conditions change.

- Drive-by-wire electronic throttle – Far more precise torque delivery and integration with variable mechanisms.

- Parts commonality – Shared architecture with the Chevy LS V8 eases repairs with readily available components.

The Gen 3 brought the 4.3L fully into the 21st century with space age materials and advanced variable engine technology. Finally shedding its crude truck reputation, this version nearly matched V8 refinement.

Cons of the Gen 3 Vortec 4300

For all its innovation, the last 4.3L generation was not without disadvantages:

- Active fuel management issues – DIS is notorious for oil consumption, lifter ticking and clogged valves requiring frequent maintenance.

- Plastic upper intake – Replaced metal intake with plastic version prone to cracking that’s an interference repair.

- Complex electronics – Drive-by-wire and advanced DIS ignition have more potential failure points. Diagnostics require advanced scan tools.

- Premium fuel recommended – High compression requires 91+ octane for ideal performance and detonation resistance under load.

- Uncertain durability – Long term reliability is unproven on all aluminum engine compared to iron block 4.3’s with 200k+ mile service life.

- Higher cost – MSRP increased around $800 over previous 4.3L making the truck-oriented engine less of a value leader.

- Scarce applications – Only continued in a few midsize trucks/SUVs so limited interchange options compared to older 4.3’s.

While innovative, the Gen 3 lost some of the everyman appeal and DIY-friendly character of the 4.3L. Complexity came at the cost of affordability and rugged dependability that endeared the engine to so many.

4.3L Engine Generations Comparison

Here is a quick overview comparing the key traits between the four generations of Chevy 4.3L engines:

Gen 1 (1985-1995)

- Carburetor or throttle body injection

- Hydraulic roller camshaft

- Distributor ignition

- Cast iron block/heads

- Most basic but stone reliable

Gen 2 (1996-2002)

- Central port injection

- Flat tappet camshaft

- Coil pack ignition

- Cast iron block/heads

- Improved power and efficiency

Gen 3 (2003-2013)

- Sequential multi-port injection

- Overhead cam variable valve timing

- Coil near plug ignition

- Aluminum block and heads

- High tech features but more complex

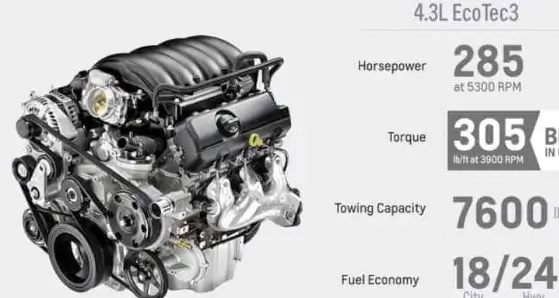

Gen 4 (2014-2018)

- Advanced direct injection

- Continuously variable valve timing

- 58X crank timing

- Aluminum block and heads

- Highest output and efficiency

The later generations of the 4.3L saw massive leaps in technology even as the engine remained focused on truck/SUV applications. Horsepower jumped from 190 to 285+ yet fundamental Chevrolet small block traits endured despite revolutionary changes.

Best Chevy 4.3L Engines by Category

Given their different strengths, each 4.3L generation shines for specific uses:

Workhorse Dependability – Gen 1

With simple throttle body injection, distributor ignition and all iron design, the original 4.3L focuses on ruggedness rather than refinement. Plus, plentiful interchangeable parts make repairs affordable.

Tunability Potential – Gen 1

The Gen 1’s cast iron block, 350 cubic inch displacement, and strong rod bolts make the 4.3L remarkably receptive to modifications. It responds well to headwork, aggressive cams, and forced induction.

Everyman Appeal – Gen 2

By blending just enough updated tech like sequential injection and DIS ignition with traditional architecture, the Gen 2 4.3L maintains affordability while improving drivability.

Maximum Reliability – Gen 2

Refinements made the Gen 2 incrementally more complex than the Gen 1 but it retained iron block strength. Teething issues were resolved by this generation, cementing its durability.

Fuel Efficiency – Gen 3

With lightweight aluminum construction, DIS cylinder deactivation, and variable valve timing, the Gen 3 4.3L finally delivered respectable fuel economy alongside its brawny power.

Peak Horsepower – Gen 4

The current generation 4.3L leverages direct injection, continuously variable valve timing, and 58x crank timing to produce up to 285 hp, nearly doubling the original 4.3L rating.

In summary, the Gen 1 remains the best pure utility motor, the Gen 2 struck the optimal balance, while the Gen 3 and 4 achieved the highest output and efficiency through modern engineering.

Frequently Ask Question

What problems does the 4.3 Vortec have?

Common issues on 1990’s to 2000’s 4.3 Vortec engines include intake gasket failures, worn lifters causing low oil pressure, clogged EGR valves, failed mass airflow sensors, damaged plastic timing gears, and collapsed spider fuel injectors.

How much horsepower can a 4.3 Vortec handle?

The 4.3L Vortec block can reliably handle around 400 horsepower in stock form before needing aftermarket block reinforcement and upgrades. With forged internals, headwork, and boost, built 4.3’s can achieve over 600 horsepower.

How do I know if my 4.3 Vortec is vortex or non vortex?

”Vortex” refers to the vortex-style combustion chambers in the cylinder heads. Non-vortex 4.3’s have conventional closed chambers without the twisted intake path. Vortec heads have heart-shaped chambers and engravings on the end indicating “vortex”.

What is the firing order on a 4.3 Vortec?

The firing order on the Chevy 4.3L Vortec is 1-6-5-4-3-2. The engine has a 90-degree bank angle, resulting in an every-other-cylinder fire sequence between the two cylinder banks. Cylinders 1-3-5 fire together and 2-4-6 fire together.

What transmission is best for a 4.3 Vortec?

The 4L60E 4-speed automatic is commonly paired with the 4.3L in trucks and SUVs. For optimal performance, a built transmission with firmer shifts helps manage the 4.3’s torque. The NV3500 5-speed manual is the desirable manual gearbox swap option.

Conclusion

The Chevrolet 4.3L V6 has an extensive history across multiple generations of trucks and SUVs. While often in the shadow of V8 engines, the little Vortec 4.3 proved its workhorse dependability hauling and towing for decades.

Each version brought incremental improvements in power, efficiency, and smoothness culminating in the high-tech VVT aluminum models. The original 1980’s era 4.3L first established the reputation for affordability and durability that loyal owners still prize today.

For those seeking maximum nostalgia or a simple project, the Gen 1 remains appealing. When improved just enough, the Gen 2 struck the perfect balance. The innovative Gen 3 proved the old school 4

Leave a Reply